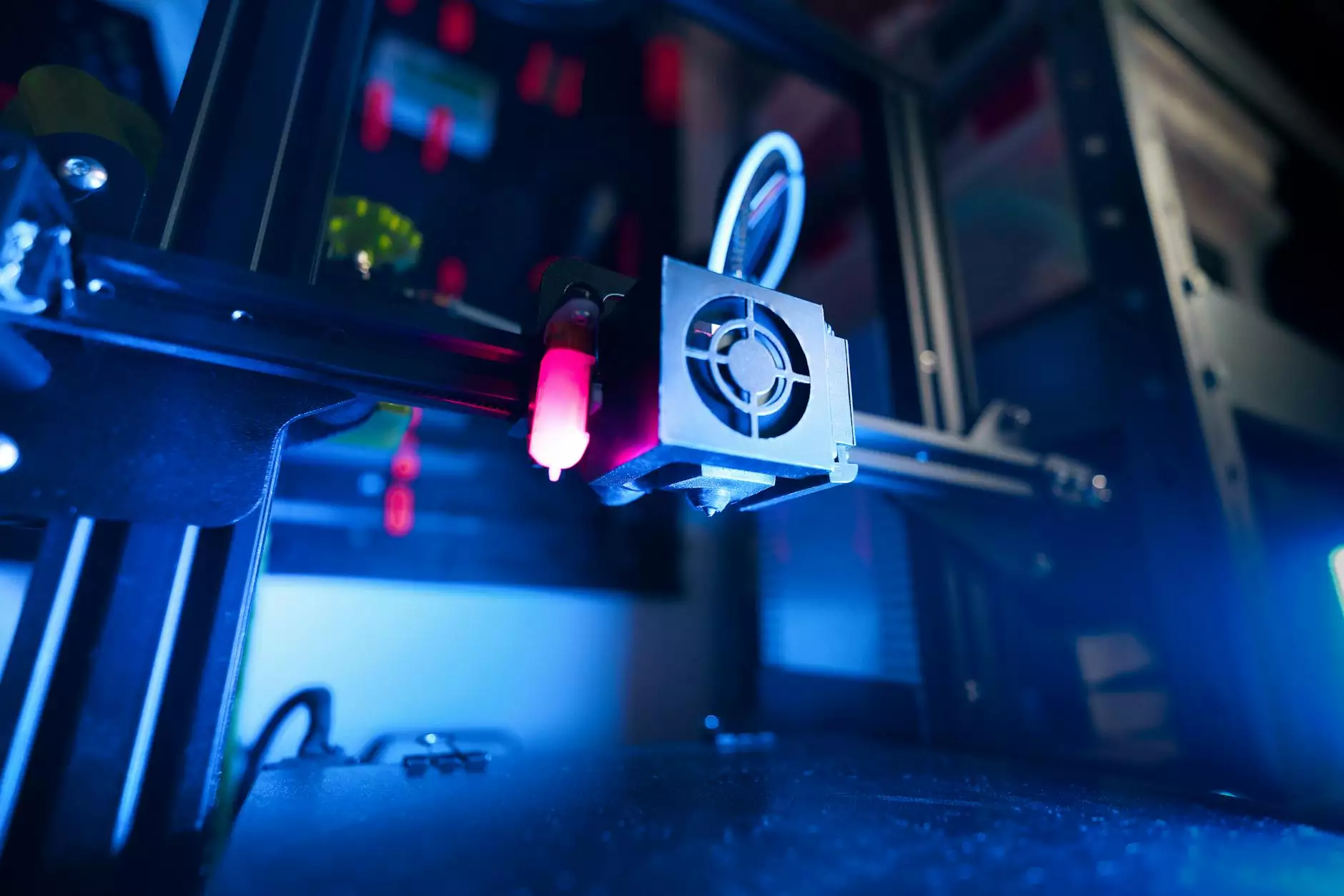

Exploring the Transformative Power of Ultim in 3D Printing

Ultim, scientifically known as polyetherimide (PEI), is a remarkable thermoplastic material that has gained significant attention in the 3D printing sector. Renowned for its superior strength, thermal stability, and resistance to various environmental factors, Ultim has carved a niche for itself in engineering and industrial applications. In this comprehensive guide, we will delve into the properties, advantages, and various applications of Ultim, particularly in the realm of 3D printing, while providing insights on how your business can leverage these benefits.

The Exceptional Properties of Ultim

Understanding the properties of Ultim is crucial for industries looking to adopt innovative materials in their manufacturing processes. Here are some key characteristics:

- High Mechanical Strength: Ultim boasts impressive tensile strength and stiffness, which makes it suitable for demanding applications that require reliable structural integrity.

- Thermal Resistance: One of the standout features of Ultim is its ability to withstand high temperatures. With a glass transition temperature of approximately 217°C (423°F), it remains stable under extreme conditions, making it ideal for applications requiring heat resistance.

- Chemical Resistance: Ultim exhibits resistance against a wide range of chemicals including hydrocarbons, various organic solvents, and other aggressive substances. This property is vital in industries where chemical exposure is common, such as aerospace and automotive.

- Low Moisture Absorption: Ultim's low moisture absorption helps maintain dimensional stability over a wide range of environmental conditions, ensuring precision in 3D printed parts.

- Electrical Insulation: Ultim provides excellent electrical insulating properties, making it a preferred choice for parts that require electrical insulation in challenging environments.

Why Choose Ultim for 3D Printing?

The 3D printing industry has been revolutionized by the adoption of advanced materials, and Ultim stands out for several compelling reasons:

1. Superior Print Quality

When it comes to 3D printing, the quality of the final product is paramount. Ultim filaments offer stunning print quality due to their ability to produce smooth finishes and intricate details. The high strength-to-weight ratio allows for the creation of robust structures without unnecessary bulk.

2. Enhanced Performance Characteristics

Parts made from Ultim demonstrate enhanced performance characteristics under mechanical stress, thermal exposure, and environmental factors. This makes them ideal for functional prototypes, tooling, and end-use parts, particularly in aerospace, automotive, and medical sectors.

3. Design Freedom

The use of Ultim in 3D printing allows engineers and designers to explore innovative geometries that may be impossible with traditional manufacturing processes. Complex shapes and lightweight structures can be realized, providing a significant advantage in competitive industries.

4. Cost-Effectiveness

While Ultim may come at a premium compared to other materials, the longevity and performance of the final products often justify the initial investment. Lower maintenance costs and fewer replacements contribute to overall cost savings in the long term.

Applications of Ultim in Various Industries

Ultim's versatile properties enable its use across multiple sectors. Here are some notable applications:

Aerospace

In the aerospace industry, where weight and performance are critical, Ultim is used for parts such as brackets, housings, and functional prototypes. Its high-temperature resistance is particularly valuable in this field.

Automotive

Ultim is frequently employed in automotive applications for both prototyping and production. Components like dashboards, clips, and housings benefit from the material's strength and durability, ensuring long-lasting performance.

Medical Devices

In medical technology, the need for materials that are both reliable and biocompatible is paramount. Ultim meets these criteria and is used in the production of medical devices, surgical instruments, and sterile packaging.

Electronics

With its excellent electrical insulation capabilities, Ultim is ideal for enclosures, connectors, and other electronic components that must withstand harsh conditions while providing safety and reliability.

Industrial Manufacturing

Ultim’s robust characteristics make it a prime material for creating jigs, fixtures, and tooling in industrial manufacturing. It aids in streamlining processes and enhancing product quality.

Conclusion: The Future of Ultim in 3D Printing

In conclusion, Ultim represents a paradigm shift in the world of 3D printing, offering unparalleled properties that cater to high-performance industries. As we continue to advance technologically, the integration of materials like Ultim will undoubtedly expand, enabling innovation and enhancing production capabilities.

At infotron.com.tr, we understand the significant impact that high-performance materials can have on your projects. By choosing Ultim for your 3D printing needs, you are not only opting for superior quality but also investing in the future of manufacturing. Explore the numerous possibilities with Ultim and stay ahead in a competitive market.

Get Started with Ultim at Infotron

If you are ready to elevate your 3D printing projects with the exceptional qualities of Ultim, visit us at infotron.com.tr. Our team is eager to assist you in selecting the right materials and technologies to fuel your innovations.

ultem